Because the components used in elevator construction must meet the highest requirements, we use the material group LiNNOTAMHiPERFORMANCE . They are extremely strong, very durable and very lightweight. Additionally, components made from these materials run quietly – an important characteristic for elevators.

Using the best materials from our own plastics production along with a modern machine park, we produce pulleys, elevator door wheels, handwheels, sheaves for systems with speed limits and speed measurements and guide rolls: precise, fast, economical – and in consistently good quality. Our manufacturing and machining capabilities belong to the top group of global companies.

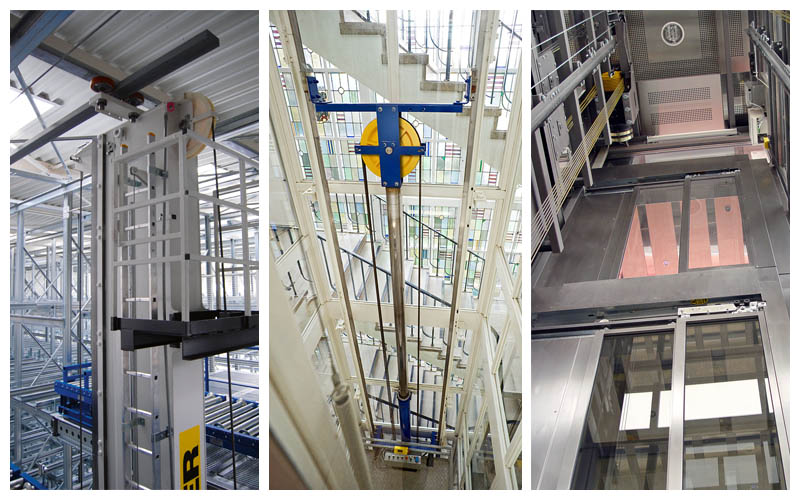

Typical applications for elevator construction components

Advantages for these applications made of LiNNOTAMHiPERFORMANCE

- high safety

- low weight

- reduced momentum

- high corrosion resistance

- low running noise

- high running precision

- cost-effective production

- tested fire performance per ENISO 11925-2:2010 as construction class „E“ / DIN 4102-4 Class B2

- continuous high strength

- secure bearing seat

- excellent fl at spot behaviour

- good creep resistance

- very long service life

- high load capacity

- low inertia

- customer specifi c design

- self balancing

Pulleys made of LiNNOTAMHiPERFORMANCE E

Longer life for elevator ropes!

Application area: Elevators

Pulleys made from specially modifi ed Cast Polyamide LiNNOTAMHiPERFORMANCE E offer the highest safety and are optimally suited for use in elevators. Due to their low weight (ca. 1/7th the weight of steel), pulleys made from LiNNOTAMHiPERFORMANCE E have a lower momentum than pulleys made from metal materials. This signifi cantly reduces the tendency to keep spinning when the elevator has stopped. In addition, their light weight makes them easier to assemble.

And another plus: The elevator ropes run over the plastic without much friction. As a result, the rope lasts longer. The pulleys not only run very precisely, they are also resistant to corrosion. They have another important benefi t: they are yellow in color and therefore do not need time and cost intensive painting.

Wheels made of LiNNOTAMHiPERFORMANCE for elevator doors

Protects the door track!

Application area: Elevator doors

In addition to the standard quality LiNNOTAM, the application specifi c modified LiNNOTAMHiPERFORMANCE 612 and 1200 make up the basis for these wheels. Wheels made from these materials have a very long service life – even under high loads. Because the material has continuous high strength, the wheels do not become brittle and there are no material fatigue cracks. The good creep resistance allows a secure bearing seat.

And another plus: Running noise is very low with these wheels because the plastic dampens well and high quality bearings are used. Because they are mechanically machined, the wheels run very precisely. Further positive characteristics are the excellent fl at spot behaviour, resistance to corrosion, wear resistance and the protection of the track.

Accessories for elevators

Optimal for high loads!

Application area: Elevator drives, speed control systems

Accessories made of LiNNOTAM such as handwheels, sheaves for speed control and measuring systems or guide wheels are proven to be extremely resilient. The individual parts are lightweight so that a low momentum and a reduced tendency to run after the elevator has stopped is achieved. Balancing of the parts is not necessary.

And another plus: The accessories are corrosion resistant. All parts are available in yellow color so that time and cost intensive painting is not necessary. The accessories are available as standard parts or can be produced to customer specifications.